Featured products Our New Arrivals

Group 1X13 Mountain Ready

From $283.00

Q Rings® Qarbon 2X BCD110X4 Aero

Regular Price

$148.00

$74.00

Aldhu 2x12s SRAM® AXS® Compatible Crankset

From $629.00

Round rings BCD110x5 Aero

From $46.00

Inspider Aldhu Carbon 1x Universal tooth Crankset

Regular Price

$1,481.00

$1,287.00

Aldhu Carbon 1x universal tooth crankset

From $727.00

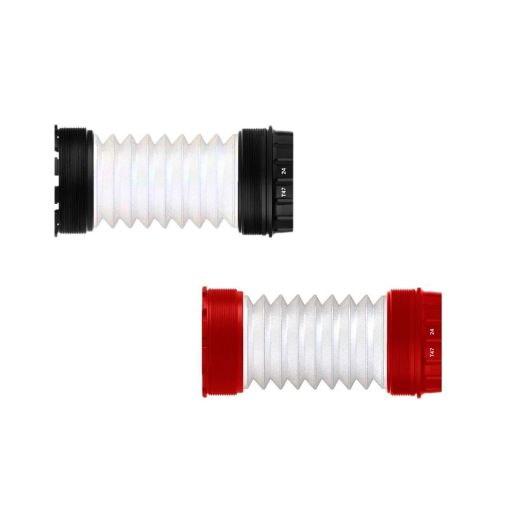

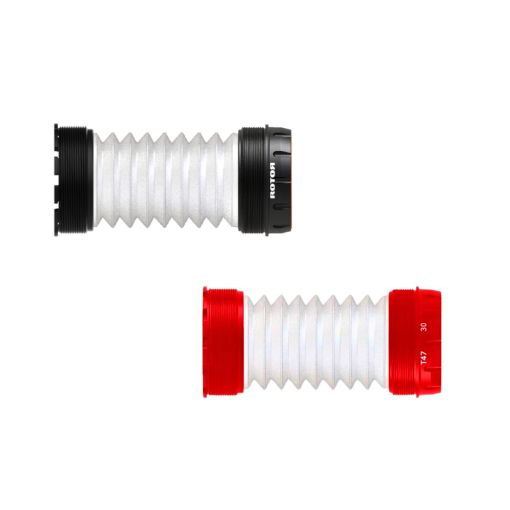

T4724 Asymetric BB

As low as

$66.00

T4730 Asymetric BB

As low as

$66.00

R-Hawk & R-Raptor axle

As low as

$66.00

Q Rings 1x Direct Mount MTB SRAM® compatible

As low as

$93.00